How to replace Dynamo with Alternator

Ok there

is nothing wrong with a properly

maintained dynamo and control box on

your imp, but only if they have been properly maintained! But either

way fitting an alternator is a good

idea as they are generally more

reliable and charge even when the

engine is idling - great for the

times you get in traffic these days.

Tools Required

Soldering Iron, Crimp Tool (correct

tool for the terminals you intend to

use), wire cutter and wire stripper

, 1/2AF sockets and spanners, 12"

straight edge, general tools

Supplies Required

Lucas Alternator Plug, 2 metres of

6mm2 wire (Red or Brown), 2 metres

of 1mm2 wire (Brown/Yellow or

Brown), a proper rear alternator

bracket but if you do not have one

of those the get some steel tube

with clearance for 5/16UNF bolts

though the centre (one like the one

between the water pump alloy and

steel brackets will do, lots of

'heavy' and 'standard' 5/16 flat

washers, some assorted 5/16UNF bolts

and nuts, some wiring loom tape (NOT

insulation tape!)/ flexi conduit

and/or cable ties, electrical test

lamp, new fan belt either an 1125 or

an 1137 (HB1125 and HB1137 at

Halfords) (buy both and return the

one that does not fit). Electrical

Terminals Pref an 5/16 / 8mm ring

terminal to suit the 6mm2 cable or

failing that a decent 10mm female

blade (lucar) connector and a male

and female blade connector with

insulation for the 1mm2 wire (bullet

connectors are also an option). You

may also wish to have a flask of

weak lemon drink to hand. (The

hobbies of Simon Quinlank)

Parts

Most alternators from the scrap yard

will work, but many these days are

huge due to all the electrical loads

on modern cars, the item that was

factory fitted to the very last Imps

is the Lucas LRA100, it was also

fitted to a number of British cars

of the same era, such as Mini's and

Viva's. Many people have also

sucessfully fitted the alternator

fitted to 80's and 90's Mini and

Metro's as they are still quite

small in size. For this article we

will be fitting the Lucas LRA100.

Section 1 - Mounting the Alternator

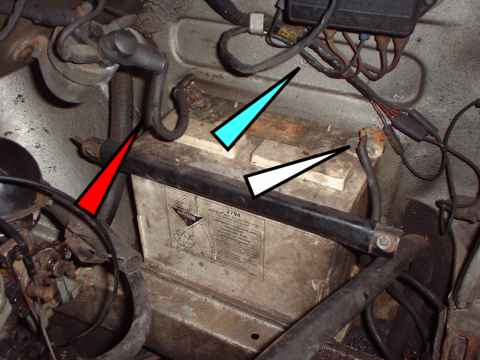

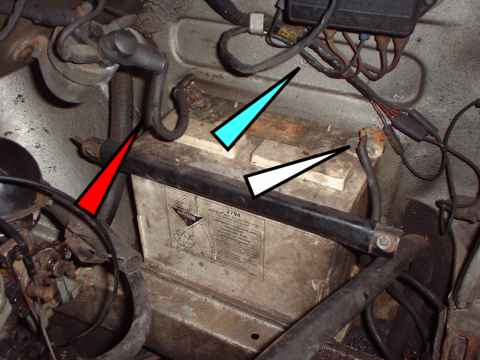

- First job when doing this is to

disconnect the battery negative

terminal (white arrow) do not do any electrical work on

you car without doing this! if you can't see which is the

negative terminal if you car is

a bit grubby, on a negative

earth car (as most imps are)

then is the wire connected to

the chassis, on an imp this the

point of attachment is a 7/16UNF

thread hole at the end of the

white arrow. The positive

battery lead is on a negative

earth car is the one that goes

to the solenoid (red arrow) See

Fig 1.

Fig 1

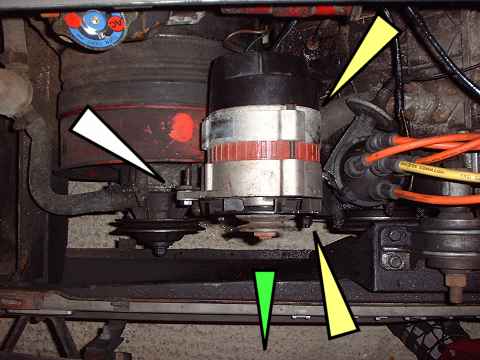

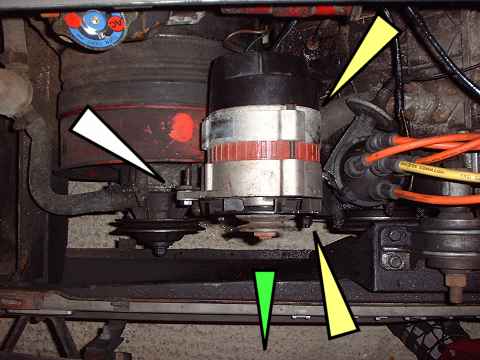

- Ok before we get involved with

the electrickery we need to do

some mechanical work. First

remove the dynamo. Slacken of

the bolts using your 1/2AF tools

as indicated in Fig 2. You will

also need to slacken of the bolt

indicated in Fig 3.

Fig 2

- You will also need to slacken of

the bolt indicated in Fig 2.

Then rotate the dynamo to

slacken the fan belt and then

remove the belt.

Fig 3

- Next reach round to the back of

the dynamo and disconnect the

large wire and small wire, these

should just pull off as they are

lucar (blade) connectors (Don't

be surprised id they literal

fall of - they did here!)

Now remove all the bolts

indicated in Fig 2, support to

dynamo while you do this to stop

it dropping away and watch your

fingers.

- With the dynamo removed you can

see rear dynamo support as

indicated in Fig 3. Now either:

- If you have a proper rear

alternator support bracket,

then you will need to remove

this bracket

or

- If you do not have the

proper rear alternator

bracket leave this one in

place as you can adapt it to

suit the alternator.

- Ok the next step is to stepback

and have a look at the

differences between the dymano

and the alt. As you see in FIg

4, the alternator is quite a bit

shorter than the dynamo. The

relation ship between the dynamo

pulley and the dynamo front

mount is nearly but not quite

the same as the alternator - the

alternator is more compact

generally apart from the

diameter! You can also see in

this picture the different rear

support brackets. The one we are

using is not a proper factory

support (this was a pressed

item) but a dynamo bracket that

has has a steel tube

welded/brazed to it to make the

distance up.

Fig 4

- Right if you have a proper rear

alternator bracket (or even a

modfied one like ours) then fit

this to the block - do not

tighten the bolts up fully at

this point as you might need to

move it around a little.

Fig 5

- Ok I can already hear some of

saying "Hey I don't

have a proper bracket, only the

old dynamo one!". Right

well for you guys this is where

the little piece of steel tube

comes in. As stated above in the

supplies listing a spare one of

those spacer tubes that normally

lives between the water pump

alloy and steel brackets is just

the job. Failing that you can

buy short bits of tube at you

local B&Q (other DIY

stores are availbale!). Just buy

a bit of steel tube (not iron or

gas pipe!) that a 5/16UNF will

fit into (take a bolt with you

to check) and try and get some

tube with thickish walls.

Failing both those options you

can (if you are a bodger at

heart!) use loads of heavy 5/16

(8mm) washers to make the gap

you, but unless you are called

Steve best get some tube!

*Tip, you will need to cut the

tube to the correct length you

need to get a nice square cut,

for this you can use a pipe

cutter (plumbing one will do

steel if you go slow). If you

don't have a pipe cutter, then

if you put a pipe clip (jubilee

etc) over the tube and tighten

it up it will give you a nice

square edge to cut againts with

your hacksaw, then just neaten

up/deburr with a file.

- Right time to mount the

alternator. It basically fits in

the same way as the dynamo, fit

the bolts to the main mounting

points first (yellow arrows Fig

6), you will need a longer

5/16UNF bolt for the rear mount

to take into account the steel

tube/rear alternator bracket

Because the distance between the

alternator and the front mount

is shorter that the dynamo, you

will need to add some washers

between the front alternator

mounting the cast alloy water

pump bracket in order to move

the alternator in the direction

of the green arrow. Nip the

bolts up (yellow arrows) so the

alternator is not wobbling

around. Then stand above the

above the alternator pulley and

visually site to see if it is in

line with the water pump/crank

pulley's. Get it close enough

using this method, you can fine

tune the alignment later. Put

the bolt in as per the white

arrow in Fig 6, you may need to

bend the adjustment bracket a

little to meet the alternator or

use washers.

Fig 6

- So now we have the basic

mechanical work done with apart

from fine tuning the alignment,

belt fitting and tightening up

all the bolts which we will do

later....it is time to move onto

the electrics! But first if you have your flask

of weak lemon drink, DRINK IT

NOW! YES ALL OF IT!

Section 2 - Electrickery

- Ok just in case you have got

this far without dissconnecting

the battery DO IT NOW! refer to point

of section one above. You should

never do any electrical work on

your imp without doing this

first, especially as they are

normally not fitted with any

fuses, your imp could end up a

burnt out wreck if you create a

short with the battery still

connected!

- First job is to make up the new

alternator cable, for this you

need to the two lengths of wire

(6mm2 and 1mm2), the alternator

plug kit, the loom tape/cable

ties/flexi conduit, the 8mm ring

terminal and the terminals you

have chosen for the thin 1mm2

wire). Now normally I perfer to

crimp connectors onto wire (as

long as you good quality crimps

and tool that is!) but in this

case I prefer to solder the

alternator terminals on the

wire, manily due to the fact

that the Lucar terminals are

'flags' (that is the wire comes

in at 90degs to the terminal)

and my crimp tool does not like,

and soldering is quick, plus

more people are likely to have a

soldering iron than a proper

crimp tool! I don't intend to

give a full lesson on soldering

here, or teach people to suck

eggs, but just a quick run down

and some tips.

- 'Tin' each part. Strip

insulation from one end of

each of the two wires and

tin the conductor, then tin

the terminals.

- Clean and tin the solderin

iron tip, this helps with

the heat transfer.

- Always heat the part to be

tinned up with the soldering

iron.

- Always feed the solder into

the item to be tinned when

it is hot enough, never melt

the solder directly with the

soldering iron..

- The solder should look

bright and shiny, if it is

dull and grey, it was not

hot enough.

- Place tinned parts together,

you can fold the crimp ears

around the wire using long

nose pliers, then heat

assembly, feed extra solder

into the assembly, when

solder flows remove heat and

keep assembly still until

cooled, joint should be

shiny and smooth, not grey

and dull.

- the big terminal is for the

6mm2 wire and the little one

for the 1mm2 wire!

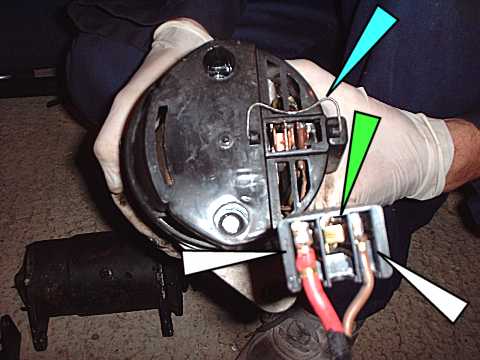

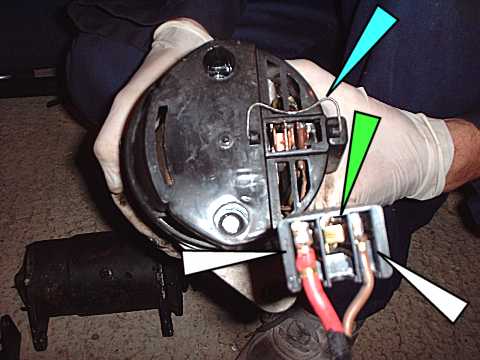

- once the solder has cooled, you

can assemble the terminal into

the alternator plug. You will

notice that there is space for

two large flags and one small,

push the small Lucar terminal

into the alternator pluh housing

until it clicks. Then insert the

large Lucar flag into the

alternator plug (Fig 7), it does

not matter which you use. Then

also insert the spare large

Lucar flag in the empty terminal

(green arrow), nothing

electrical about this last step

but will help stop the

alternator plug coming loose if

you no not have a alternator

plug clip (blue arrow). Be sure

to push all the terminal into

the housing until they click.

Then clip the back of the plug

on.

Fig 7

- Now before you fit the new loom

you need to get to the right

length, so loosely plug the

alternator plug into the

alternator, then run the cables

as per Fig 8, just temp hold the

wires to the car etc with

string/tape/cables ties. Make

sure you put a bit of slack as

marked in Fig 8 by the arrows.

Fig 8

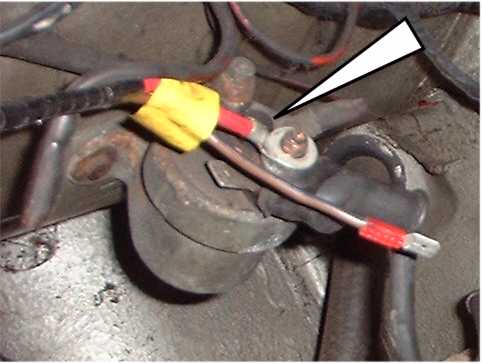

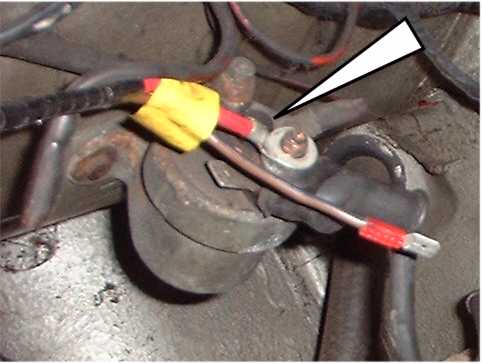

- Disconnect the large Lucar

terminal arrowed in Fig 9, just

tuck the wire and terminal out

of the way for now.

Fig 9

- Ok trim the 6mm2 cable to length

and crimp on the 8mm ring

terminal so that it will line up

with the post (the one that the

battery lead is attached to, and

NOT the one the starter cable is

attached to) on the solenoid as

per Fig 10. Ignore the thin in

Fig 10 for the time being.

Fig 10

- Now onto the control box, Fig 11

show the item with clearer

terminal markings, you should be

able to see the markings moulded

into the black cover. It looks

confusing but is quite simple.

- 'D' - the fat wire connected

to terminal D is the other

end of the fat wire that

used to go to the back of

the dynamo

- 'W/L' - Simple this one, W/L

is the wire that goes to the

little red light on the

dashboard or in the binnicle

- 'F' - the thin wire

connected to terminal F is

the other end of the thin

wire that used to go to the

back of the dynamo

- 'B' - One of these fat wires

goes to the ignition switch,

the other goes to the

solenoid and is the one you

disconnected in Fig 9

Fig 11

Terminal 'B' is a common

terminal so it does not matter

which way round the two fat

wires are conected, but you need

to know which is which! First

disconnect the two wires from

the control box. Method one is

to connect a powered test lamp

or continuity tester (on every

digital multimeter) to the

terminal you disconnected in Fig

9 above then buzz out the two

wires you have just disconnected

from the control box one at a

time - the one that lights the

lamp or sounds the buzzer is the

wire YOU DO NOT NEED, mark both

ends of his wire with

tape/marker pen so you know

which it is (we will call this

wire the solenoid wire). If you

don't have a test lamp or a

continuity tester you can ID the

wires physically by unwraping

the loom and seeing which is

which, you want the fat brown

wire that goes between the 'B'

terminal and that dissappears

with the rest of the loom into

the car (we will call this the

wire the power wire) and NOT the

fat brown wire that goes to the

solenoid (solenoid wire).

- Now unwrap the loom and move the

'power'fat wire and the thinner

brown/yellow wire that was

connected to W/L from their

current positions marked with

dotted lines (Fig 12) to their

new positions marked with solid

lines (Fig 12). You will not now

the fat brown wire goes to large

(10mm) male lucar terminal, you

may need to trim the length of

the wire a little and also check

the condition of the terminal on

the end of the fat brown wire,

if in doubt replace with a new

10mm female lucar terminal. You

will also note that the thin

brown wire with the yellow strip

or 'tracer' needs connecting to

the thin wire in you newly made

alternator loom. You can make

this connection with a male and

female lucar terminals of bullet

terminals, now you can trim the

thin wire in yoru alternator

loom to length. Ok that is the

difficult electrical bit done,

now you just need to make good

all the connections and tidy the

wiring up.

Fig 12

- Remove the alternator loom and

wrap with loom tape (remember DO

NOT use insulation tape it is

rubbish for this job), or bundle

the alternator loom together

with cable ties at regular

intervals, or run the wires

through some small diameter

flexi conduit. Then once you

have finished the loom you need

to clip and secure the loom to

the car, you can do this by

cable ties to the existing loom

bundle. Make sure you leave some

slack at the alternator end to

allow for engine movement, plus

the alternator plug firmly into

the alternator and then if you

have one pop the retaining clip

on. Now at the other end undo

and remove the nut and spring

washer on the solenoid post

(remember one the battery lead

is attached to) and fix the 8mm

ring terminal to the stud, refit

the washer and nut and tighten.

Reconnect up the thin wires and

bundle up with the rest of the

cars loom. You can now remove

the control box, you can leave

the old dynamo wire and the

'solenoid' wires in place just

tuck the ends out of the way and

wrap in loom tape (you could of

course remove all the redundant

wires if you wished and then

rewrap all the engine bay wires

for a neat look)

Section 3 - Aligning the Alternator

pulley

- You might remember that the

alternator is roughly mounted in

place, but it needs to be

aligned as accurately as

possible to ensure the water

pump and alternator bearings are

no overloaded and the belt does

not wear out too quickly.

- As per Fig 6 above the main

mounting bolts should be fairly

tight, you now need to check the

alignment of the alterntor

pulley in relation to the water

and crank pulley's - getting

this wrong with at best wear the

fan belt rapidly or at worst

loose it and also damage the

alt/water pump bearings. Make

sure the main mounting bolts (so

the alternator is not tipping)

are tight fit a fan belt then

swing the alternator up to make

the belt tight.use a straight

edge such as a steel rule to

check alignment. (fig 13)

Fig 13

- insert/remove washers in the

area indicated to get the

correct alignment - a little tip

is get a selection of 'heavy'

and 'standard' 5/16 washers as

they are different thicknesses;

useful for gettingthe right

thickness ie two thick, one

thick one thin, two thick one

this etc.

It is also worth using the steel

rule in other planes plus

sighting along the fan belt runs

to check the alignment.

Section 4 - Testing

- Ok adjust up the alternator

using the adjuster bracket to

get the correct fan belt tension

(about 1" slack in the

centre of the longest run water

pump to crank pulley)

- Make sure all the mountings are

tight.

- Make sure the alternator plug is

fitted in to the back of the alt

- Make sure the other electrial

conections are correct, spinning

the alt up with out it being

connected up WILL DAMAGE IT

- Make sure the noting is going to

dangle / get tangles up in the

engine (such as the old wiring

if you have left it in place).

- Reconnect the battery - Nothing

should happen at this point!

- Ok ready for a test. First check

that the ignition warninglight

is not blown - this is now an

essential part of the new

charging circuit - if it is

blown the alternator will not

work properly (see Aldrins

comment - a resistor is a good

idea).

- Turn the ignition key one click

- the ignition (red) warning

light should light up.

- Start the car, the red light

should now go out! Ifit does not

there is a problem -switch off

and investigate. If it does got

out you can also check the

output by using multi meter

across the battery even at a

fast idle voltage should be

13volts +

(c) Andy Smith 2025